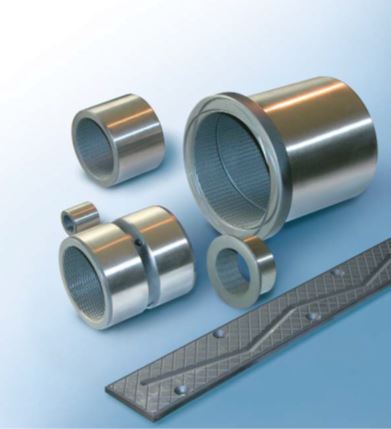

High pressure resistance to wear and seizure.

Bearing manufactured from steel with a cross- hatched configuration of the bearing surface and a thermo- chemical surface treatment plus impregnation. This bearing has an excellent resistance to wear and seizure and is particulary suitable for very high contact pressures.

Surface characteristics

The friction area has a multitude of interconnecting channels, preferentially oriented in the direction of motion. These channels provide a reservoir of lubricant in case of random lubrication, a better load distribution, and and efficient removal of abrasive particles from the contact. The thermo- chemical treatment plus impregnation provides a high surface hardness, a good conformability and an excellent resistance to wear and seizure.

Conditions of use

– up to 100 N/ mm² ( psi) (contact pressure calculation based on projected area)

– above N/ mm² (71 psi): consult us

– 0 to 30 m/ min. (0 to 90 ft/ min.)

– above this: consult us

all oils and greases are satisfactory with the exception of greases loaded with graphite, copper or other metallic compounds

– up to 300°C (570°F)

– above this temperature: special bearings for higher temperature applications can be manufactured

– 0.03 to 0.3 mm

– according to the diameter and the applications

– opposed shafts or pins

– P-NR technology surface hardened shafts up to 60 HRc + hard chromium

– P-CR technology surface hardened shafts up to 60 HRc

– we can supply these shafts and pins

– joints for dump trucks

– bearing blocks for lifts and elevators

– bearings of piston pump connecting rods

– chain conveyors

– mould closing articulators

– open hearth furnace mechanisms

– bearing blocks for agricultural machinery

– tractory front axle joints

– leaf spring bearings

– bearings for braking linkage