Cast ceramics: the raw materials alumina Al₂O₃, ZrO₂ and SiC are fused in a furnace and cast in moulds. This production process makes it possible to cast complex parts.

Advantages:

- perfect impact resistance

- thermal shock resistance

- abrasive wear resistance

- during the casting, metallic inserts can be placed

- adapted to frictional wear

Cast basalt

Cast basalt is a mineral product with high hardness.

The volcanic rock is milled and fused in a furnace at 1280°C and cast in moulds.

The surface is very smooth, so the product is well adapted for frictional wear.

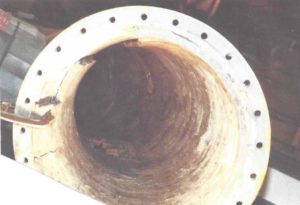

Visuals cast basalt

|  |  |

Properties and advantages:

- high hardness and wear resistance

- chemically by inert

- no water absorption

- very good resistance to sliding wear

Technical information

| hardness Mohs | 8 |

| specific weight kg/m³ | 2900 |

| compressive strength MPa | 450 |

| water absorption | 0 |

| coefficient of thermal expansion W.m-1 .K-1 | 1.9 |

Applications

- wear resistant linings in hydraulic transport of abrasive and erosive material

- tubes and bends in pneumatic conveying systems, reduction parts, T-pieces, Y-pieces, parts according to drawing

- lining of chutes, cyclones, chain conveyors, hoppers, mixers, …

|  |