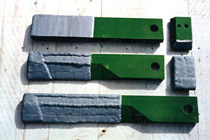

Illustrations tungsten carbide hardfacing

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

Description tungsten carbide hardfacing

Manual gas deposit tungsten carbide hard surfacing: Fused tungsten carbide, one of the hardest and most abrasion resistant materials, with hardness between 3000 and 4000 HV in a metallic auto fusible Ni / Cr / B / Si matrix is deposited by an oxy-acetylene flame. The melting point is low, approximately 1050°C, much lower than an electric arc deposition.

By this low temperature gas deposit the deformation of the base material and the crack forming are limited.

The spherical form of the tungsten carbide enhances the impact strengths and the abrasion resistance. The gas deposit system improves the density of the compact and crack free hardfaced layer.

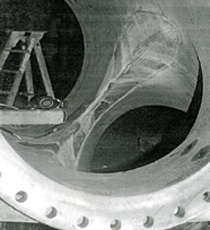

Applications tungsten carbide hardfacing

stabilisers, dredging teeth, deep drilling equipment, tunnelling shields, earth moving machines, conveyer screws, mixer blades, milling plates, down whole reamers, mixer paddles, scraper blades, extruders in the brick industry,….

Technical information tungsten carbide hardfacing

Tungsten carbide particle size: from 0.3 till 2.2 mm in different product classes.

Hard facing layer thickness: 1 – 12 mm.