Sintered tungsten carbide hardmetals are manufactured by a powdermetallurgy process. Tungsten carbide powders are sintered with a binder Co or Ni pressing the metal particles into a mold and sintering the material in a furnace during a period ranging from 20 – 200 minutes and a temperature around 1400 °C in a protective atmosphere.

Sintered tungsten carbide hardmetals are manufactured by a powdermetallurgy process. Tungsten carbide powders are sintered with a binder Co or Ni pressing the metal particles into a mold and sintering the material in a furnace during a period ranging from 20 – 200 minutes and a temperature around 1400 °C in a protective atmosphere.

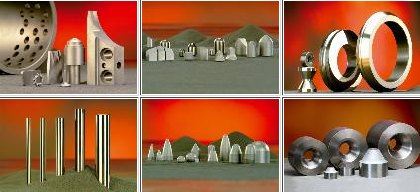

This dense material is cemented and used as wear resistant parts which can be fixed by brasing on a substrate. Cemented or sintered tungsten carbide components are used for many applications that require wear resistance and long lasting.

Tungsten carbide is a tough, high strength material.

Applications:

- shaped tips for woodworking

- seal rings

- cutting tools

- die parts

- discs

- blasting nozzles

- metal slitting saws

- drills for brick and concrete

- shisels

- groovers

- tools for cutting paper, textile, glass fiber, mineral wool and cardboard