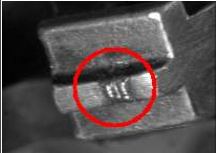

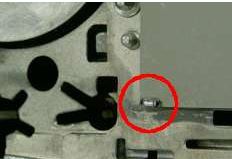

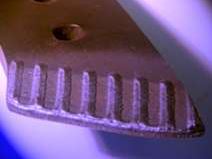

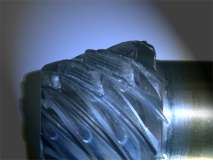

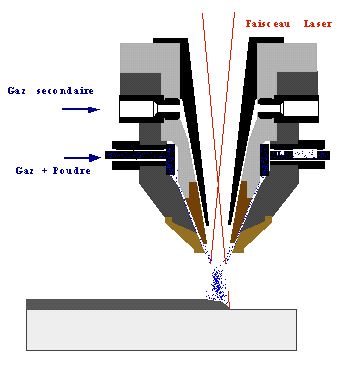

Illustrations of laser cladding

Characteristics of laser cladding

Laser cladding is the technology for wear resistant hardfacing of the future. A metallic powder or wire is molten in the laser beam and deposited onto a metal substate. The nozzle system can either be co-axial or lateral. The laser beam has two funtions, preheating the substrate and melting the metal powder or wire.This way a perfect metallurgical bond between substrate and deposit is assured.

Advantages of laser cladding

- automatic CNC process

- deposit thickness 0,3-2 mm/layer

- high precision in the deposit layer: tolerances 0,1 mm

- perfect metallurgical bonding, no risk for debonding

- no porosity, high density of the deposit

- no cracks

- delution with the substrate: less than 1 %, so the optimal characteristics of the deposit are assured on the whole thickness

- heat-affected zone (HAZ) reduced and virtually no deformation

- a wide range of deposit metals

|  |

|  |

|  |

|  |

|

|

Applications for laser cladding

- repair of worn out parts and tools

- wear resistant hard facing

- turbine parts

- corrosion protection deposits based on steel, tool steel (M2, M4,…) , stainless steel 300, 400,..

- cobalt based: stellite 1, 6, 12, 21, 25

- nickel based: Hastelloy, NiCrBSi, Inconel 600, 625, 718,…

- aluminium based: Al + 5 à 60% Si

- copper based: Cu + 10% Al,…

- carbides: tungsten carbides, titanium carbides, Ni Cr B Si,…