SIOSIC® is a new 2-component ceramic for abrasive and corrosive high temperature applications, as an alternative to the complex and cost-intensive repair measures.

The cold hardening SIOSIC® can be used for repairs or coating protections of surfaces in high temperature applications ranging between ∆T = -150 °C to +1200°C (wet 700 °C, dry 1200 °C). This implicated lower operating costs and longer life time.

Characteristics:

- can either be used to rebuild a worn metal surface or as a preventative coat-ing

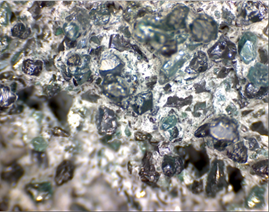

- has a high content of silicon carbide which is nearly as hard as a diamond and consequently extremely wear resistant, it often outperforms the original metal in terms of abrasive stability

- a wear protection for repairs and / or for protection of surfaces being in abrasive and corrosive applications pH 0-14

- a matrix of a non-organic silicate polymer fill with 70% silicon carbide

- a non-hazardous good, mixed with water it can be easily applied on the surface

- Applications:

- afterbunners

- furnaces

- kettles

- incinerators

- flue gas inlets

- air preheater

- heat exchanger

- pumps

- pipings

- sockets

- flanges